Smart Light Pole Buyer's Guide 2026: A Comprehensive Framework for Selecting, Deploying, and Managing Intelligent Urban Infrastructure

February 12, 2026 — As cities worldwide accelerate their digital transformation, the humble street light pole is evolving into a critical piece of urban tech infrastructure. The global smart city market, valued at over USD 1.2 trillion, is driving unprecedented demand for smart light poles. These are no longer just supports for lighting; they are multi-functional platforms for connectivity, environmental sensing, security, and public services. For municipal planners, project developers, and procurement officers, navigating the complex landscape of smart light pole solutions can be daunting. This comprehensive buyer's guide, informed by industry leaders like LANDMARK, provides a step-by-step framework to make informed, future-proof purchasing decisions.

1. Defining Your Project Requirements and Core Objectives

Before evaluating suppliers, clearly define what you want your smart light pole network to achieve. Objectives typically fall into several categories:

- Enhanced Public Safety & Security: Integration of CCTV, emergency call buttons, and gunshot detection.

- Digital Connectivity & 5G/6G Rollout: Hosting small cells, Wi-Fi access points, and IoT gateways.

- Environmental & Traffic Management: Equipping poles with air quality sensors, noise monitors, traffic counters, and smart parking sensors.

- Operational Efficiency & Sustainability: Using adaptive LED lighting controlled by motion sensors or schedules, often paired with solar light pole technology for off-grid areas.

- Aesthetic & Urban Integration: Ensuring the pole design complements the cityscape, which may involve decorative light pole elements or custom finishes.

A project for a downtown revitalization will prioritize aesthetics and connectivity, while a highway or port project might focus on structural resilience for a high mast and sensor durability.

2. Critical Technical Specifications and Evaluation Criteria

The physical and technical backbone of the system is the pole itself. Here’s what to scrutinize:

A. Structural Integrity and Material Science

The choice of material directly impacts longevity, maintenance, and load-bearing capacity.

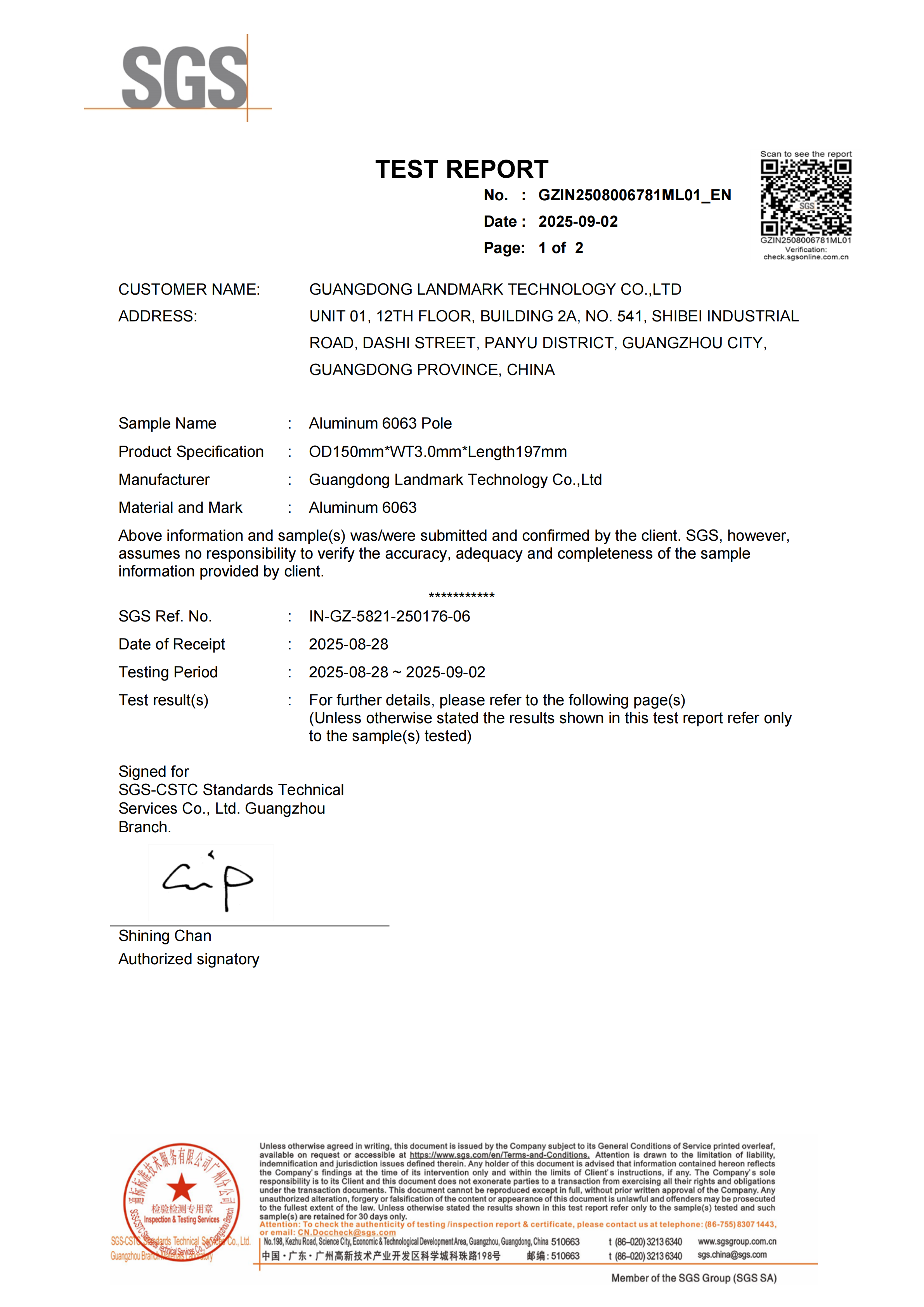

- Aluminium Light Pole: The preferred choice for smart light poles due to its excellent strength-to-weight ratio, inherent corrosion resistance (crucial for coastal or high-pollution areas), and ease of installation. It requires less structural foundation than steel, reducing initial cost. Suppliers like LANDMARK use high-grade aluminium 6063, verified by material composition certificates.

- Steel Light Pole (Galvanized): Offers superior ultimate strength for very tall structures or heavy sensor arrays. Must be hot-dip galvanized to ASTM or EN standards for corrosion protection. Requires rigorous inspection of welding and coating.

- Stainless Steel Light Pole: Used in highly corrosive environments (chemical plants, marine fronts) or for premium aesthetic appeal. The most expensive option but offers exceptional lifespan with minimal upkeep.

Always request third-party structural calculation reports based on relevant standards (AASHTO, EN40, ANSI) for wind load, ice load, and seismic activity. For direct burial aluminium light pole installations, verify the wall thickness and corrosion protection at the burial section.

B. Corrosion Protection and Longevity

This is non-negotiable. A failed coating leads to catastrophic structural failure and high replacement costs.

- For Aluminium: A high-quality powder coating (polyester, polyurethane) over a chromate conversion coating is standard. Look for salt spray test reports (e.g., ASTM B117) showing 3000+ hours to red rust for steel substrates or no corrosion for aluminium.

- For Steel: Hot-dip galvanizing (HDG) per ASTM A123 is mandatory. The coating thickness should be appropriate for the environment (e.g., thicker for marine zones). A powder coat topcoat can add color and extra protection.

Companies with dedicated corrosion expertise, like Guangdong Landmark Technology Co.,Ltd, can provide customized solutions for extreme environments, backed by test reports such as their Salt Spray Test of Steel Pole Powder Coat Finish.

C. Smart Integration and "Future-Proofing"

The pole must be designed as a platform, not just a pipe.

- Internal Conduit and Cable Management: Ample, accessible internal space with pull strings for easy cable routing. Separate compartments for power and data cables may be required.

- Standardized Mounting Interfaces: Look for poles with pre-drilled holes, standardized brackets (e.g., NEMA, proprietary), or modular attachment systems for cameras, sensors, and antennas.

- Power and Data Access Points: Strategically placed waterproof electrical cabinets (NEMA 4X rated) with sufficient outlets, Ethernet ports, and circuit breakers.

- Foundation and Power Supply: Determine if the system will be grid-tied, solar-hybrid, or a standalone solar light pole. The foundation design (direct burial or anchor bolt) must account for the added weight and wind load of all attached devices.

3. Supplier Evaluation: Beyond the Product Spec Sheet

Choosing the right manufacturing partner is as important as choosing the right pole.

A. Engineering and Design Capability

Can the supplier contribute to the design? LANDMARK, for instance, distinguishes itself with a team of Ph.D. and Master engineers who provide structural design and verification services per AASHTO and EN standards. They also have a professional exterior design team for custom decorative light pole solutions that reflect local culture, making them ideal for tourism or landmark projects.

B. Quality Assurance and Certifications

Demand transparency. A reputable supplier will readily provide:

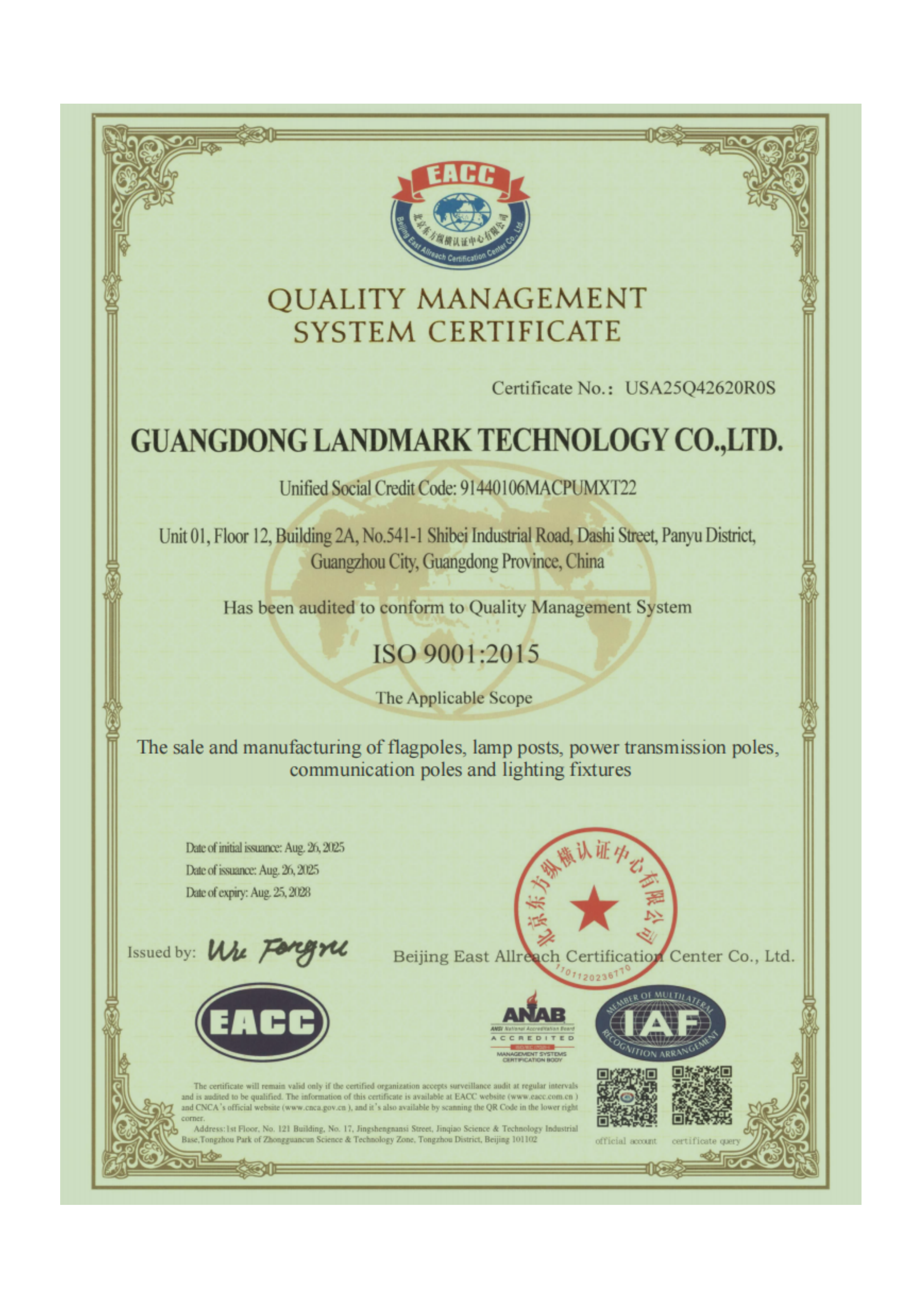

- ISO 9001 Certification: Proof of a managed quality system.

- Material Test Reports: For aluminium alloy, steel grade, and coating materials.

- Welding Certificates (e.g., CWB): Critical for steel poles. Request non-destructive testing reports like Magnetic Particle or Dye Penetrant testing.

- Performance Test Reports: Salt spray tests, load tests, and hardness tests.

LANDMARK's portfolio includes all these, such as their Hot Dip Galvanized Coating Test Report and Welding Dye Penetrant Testing Report, demonstrating commitment to international standards.

C. Manufacturing Scale, Logistics, and After-Sales Support

Evaluate their ability to deliver your project on time and support it for decades.

- Vertical Integration: Companies that control R&D, design, production, and finishing (like LANDMARK) ensure better quality control and flexibility.

- Global Project Experience: Have they supplied poles for large-scale events, municipal projects, or government approvals in markets like the UAE, USA, or Australia? This experience is invaluable.

- After-Sales Service: What is their policy on technical support, spare parts, and warranty? A 15-20 year warranty on the structure and coating is a good benchmark.

4. Total Cost of Ownership (TCO) Analysis

The initial purchase price is only part of the story. A higher-quality aluminium light pole may have a higher upfront cost than a basic steel light pole, but its TCO is often lower.

- Installation Cost: Lighter aluminium light poles reduce shipping costs and require smaller cranes and foundations.

- Maintenance Cost: Superior corrosion protection means no repainting or rust treatment for 20+ years. Aluminium does not rust.

- Energy Cost: Integrated smart lighting and solar light pole options can slash electricity bills by 50-70%.

- Failure Risk Cost: A pole failure can cause injury, damage, and immense liability. Investing in certified quality mitigates this risk.

5. Implementation Roadmap and Partner Selection

- Pilot Deployment: Start with a small cluster of smart light poles to test technology integration, public reception, and operational workflows.

- Choose a Strategic Partner, Not Just a Vendor: Select a manufacturer like LANDMARK that can act as a solutions provider—offering structural design, corrosion consulting, and custom aesthetics alongside manufacturing.

- Phased Rollout: Scale the deployment based on pilot learnings, budget cycles, and infrastructure readiness (e.g., fiber optic backbone).

- Data Management Strategy: Plan for the collection, storage, security, and analysis of data from the pole's sensors from day one.

Investing in a smart light pole network is a strategic decision that will impact a city's functionality, safety, and sustainability for a generation. By meticulously following this guide—focusing on robust materials like aluminium, demanding verifiable quality certifications, and selecting an engineering-driven partner like Guangdong Landmark Technology Co.,Ltd (LANDMARK)—municipalities and developers can ensure their investment builds a resilient, intelligent, and connected urban future.

For expert consultation on your smart city lighting project, contact LANDMARK today:

Phone: +86 13927796733

WhatsApp: +86 18318897233

Email: sales02@landmark-innovation.com

Website: www.landmark-innovation.com

Address: 1201, 2A, Smart Creative Park, Shibei industrial road, Dashi street, Panyu district, Guangzhou city, Guangdong Province, China.